of the Supply Chain

Value chains under pressure from external factors

Demanding high performance to maintain a strong competitive edge

-

Fragile supply and distribution chains

-

Complex, constantly reconfiguring flows

-

Severe pressure on resources

-

Increasingly volatile demand

-

New requirements or regulations linked to the ecological transition

-

Focus on availability and therefore on sales, which are less and less guaranteed

-

Improving stock quality to deal with both the risk of stock-outs and the risk of obsolescence

-

Staying competitive in spite of everything :

- Being agile while keeping costs under control,

- With serene, efficient teams! -

Produce nothing unnecessary

Reduce high-impact transport

Sustainable teams

Value chains under pressure from external factors

-

Fragile supply and distribution chains

-

Complex, constantly reconfiguring flows

-

Severe pressure on resources

-

Increasingly volatile demand

-

New requirements or regulations linked to the ecological transition

Demanding high performance to maintain a strong competitive edge

-

Focus on availability and therefore on sales, which are less and less guaranteed

-

Improving stock quality to deal with both the risk of stock-outs and the risk of obsolescence

-

Staying competitive in spite of everything :

- Being agile while keeping costs under control,

- With serene, efficient teams! -

Produce nothing unnecessary

Reduce high-impact transport

Sustainable teams

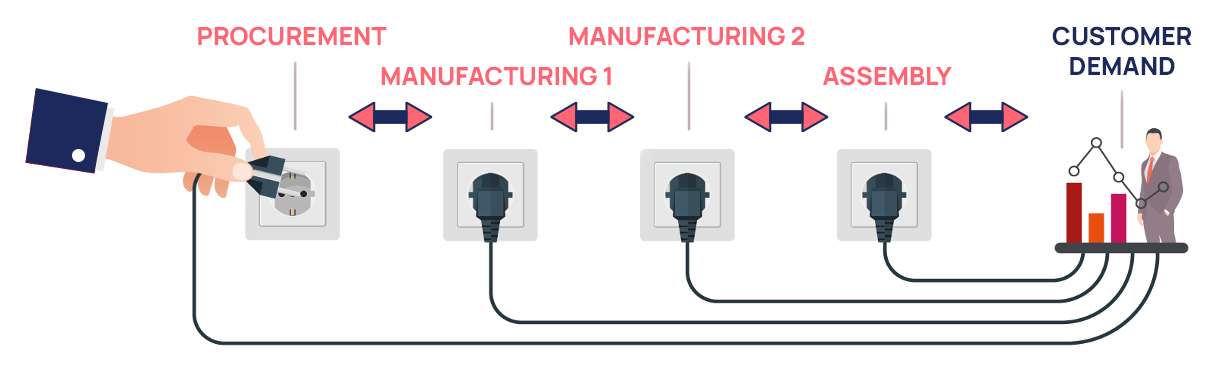

The MRP is

on / off

each order movement triggers an alert, without the consequences or severity being identifiable

The MRP has

one signal only

and forces an impossible trade-off between “building a realistic plan and losing priorities”; or “keeping priorities and not knowing when products will be delivered“

The MRP is

sequential

an upward or downward movement in demand can take weeks to be perceived at the other end of the chain, severely limiting agility

Connect each Supply Chain player to the “real demand”, that of the end customer

In concrete terms, this means providing each actor involved in the flow with the information - the signal - of what he “Must-Do” to satisfy the customer's request, independently of what the others are going to do

Operations are planned on the basis of this “Must-Do” signal

Everyone instantly has the same vision of priorities, being connected to customer demand

Each person acts in parallel at his or her own level to remove constraints, whether in terms of capacity or supply: the overall constraint is thus broken down into as many individual actions

Everyone understands the meaning of their actions and their impact on the end customer

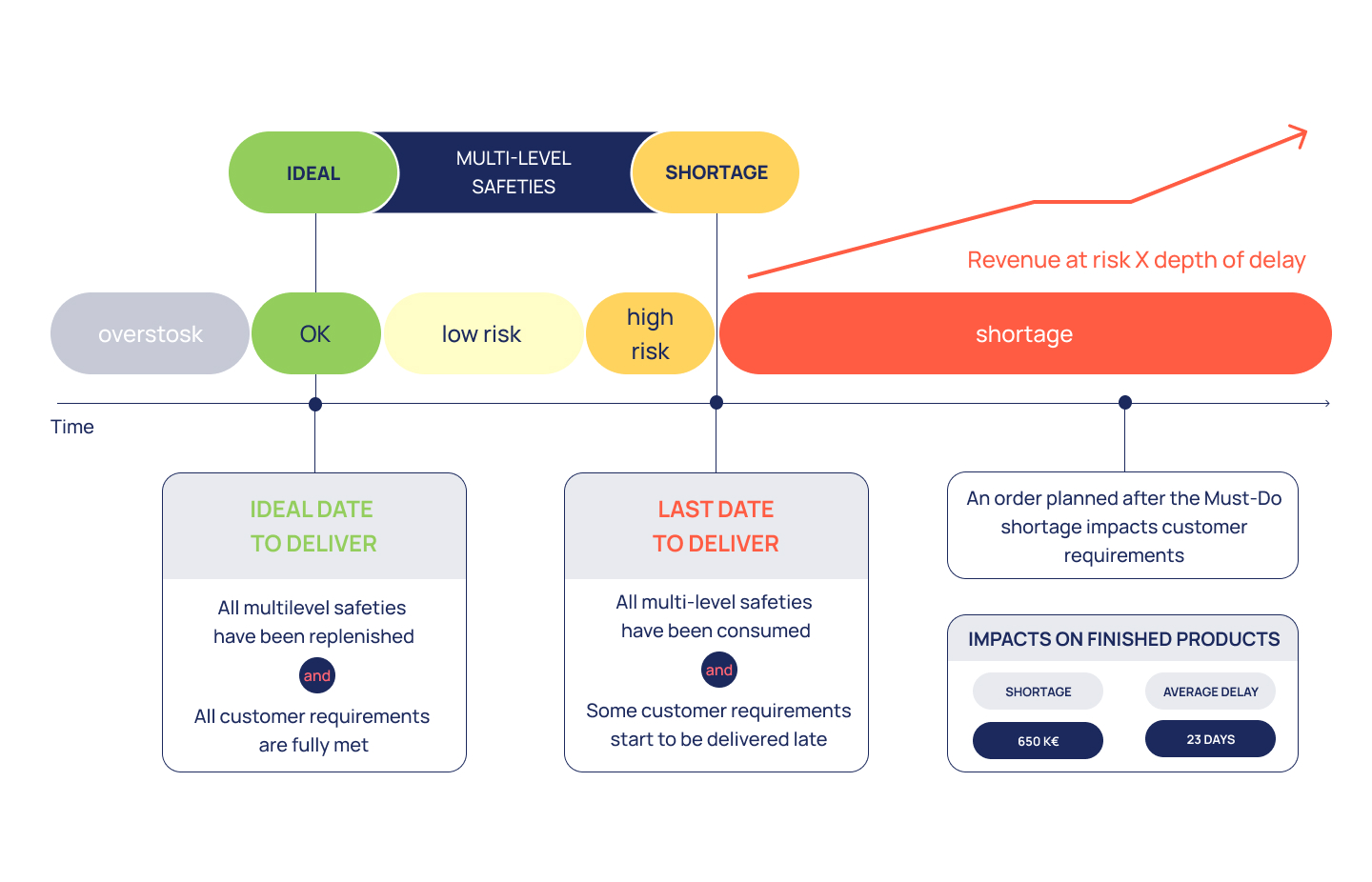

The ”Must-Do” is not on/off signal as the MRP, it consists of two dates to manage the level of priority

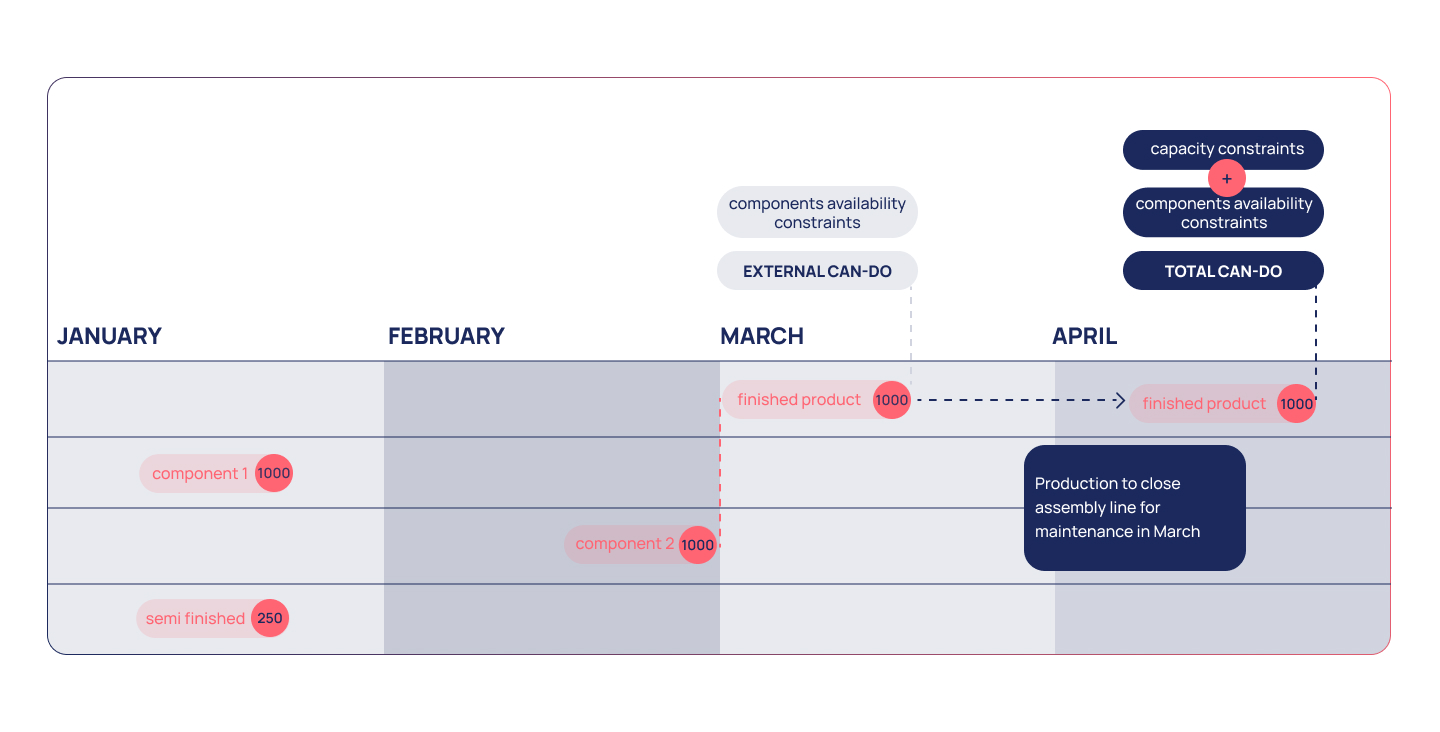

Provide visibility on what the Upstream Supply Chain is actually capable of doing, given capacity and component constraints

This principle is materialized by a second signal called “Can Do”

The organization is able to monitor its level of response to customer demand at all times

Each link in the chain can also see its level of contribution to the unserved demand, and can therefore take informed action to remedy the situation

No Chain Planning fills the gaps left by the MRP, providing the agility needed to meet demand and avoid unnecessary overstocking and instability

The MRP is on / off

The Must-Do Allows all stakeholders to focus on the right priorities.

The MRP has one signal only

2 signals are available at all times: Must-Do and Can-Do. We simultaneously manage the feasibility of the plan and customer priorities.

The MRP is sequential

Thanks to Must-Do, a change in customer demand is instantly propagated to all parties in the supply chain, resulting in a more responsive supply chain.

Concrete impacts on processes

Stabilization of plans and a shared vision of the same signal also generate gains in efficiency and peace of mind for operational teams.

Service

revenue at risk reduction

Stock

inventory reduction

Cost

Ramp-up scalability without extra resources

Sustainability

Reduction in obsolescence costs

Request a

personalized demo

Contact us to start the transformation of your Supply Chain